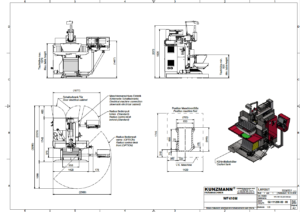

WF 410 M

Highlights

KUNZMANN’s WF 410 M is the latest manual milling machine

with a positioning control on the market

– a must-have for workshops, manufacturing, and training: No matter what your processing needs are: The WF 410 M is the perfect solution in terms of high-performance, perfect precision, and easy handling.

The special KUNZMANN features:

- solid cast column construction with vertical milling spindle and manual quill

- hardened and ground flat guideways in all axes

for maximum stability - zero-clearance ball screws for up and down milling

- constantly high long-term accuracy

- infinitely variable feed and speed drives

- automatic mechanical tool clamping

- manual handwheels in all axes

- coolant tank, free-standing, 66 liters

- ergonomic and convenient operation concept

- HEIDENHAIN TNC 128 positioning control including functionality of 3-axis active digital readout

| WORKING RANGE | |

| Longitudinal | 410 mm |

| Cross | 350 mm |

| Vertical | 450 mm |

| Main drive (100%/25% of duty cycle) | 8.5/16.2 kW |

| Spindle speed | 1-4,500 rpm |

| Tool taper | SK 40 DIN ISO 7388-1 (formerly DIN 69871) |

| Feed | up to 5 m/min |

| Readout/positioning control | TNC 128 |

| Weight | approx. 1.900 kg |

| Rigid angular table | |

| Clamping surface | 650 x 375 mm |

| T-grooves | 5 x 14 H 7 |

| Table load | 250 kg |

Rigid angular table

Clamping surface: 650 x 375 mm

T-grooves: 5 x 14 H7

Table load: 250 kg

Universal tilting-swiveling table

The universal tilting and swiveling table allows you to position the workpiece in different angular positions. Adjustment is done manually with the rotation angle of the clamping plate being indicated on a digital readout.

- adjustable in 3 axes

- rotational angle: 360°

- swiveling range: +/-30°

- tiltable away from machine by 15°, tiltable towards machine by 35°

- table dimensions: 650 x 395 mm

- 6 T-grooves 14 H7 (63 mm clearance)

- centering hole: 32 mm

- max. table load: 220 kg

Electronic handwheel

The portable device supports the operator in setting up and retooling the machine due to a close view on the working area.

The handwheel features axis keys, keys for feed rates, and control keys for the machine.

Horizontal spindle and arbor holder

For horizontal milling, you can conveniently separate and pivot the vertical milling head on a support arm.

A further option is working with an arbor holder for additional stability.

It allows the use of long cutter spindles with one or more disk milling cutters up to a diameter of 150 mm.

PLEXIGLAS® splash protection

The protective windows are attached to the angular table and can be hinged up and down.

Splash guard cabin

The cabin offers excellent accessibility to the working area through two large front sliding doors and an additional door on the right machine side.

Automatic Full Sequence Run Mode

In combination with our limit-switch protected cabin, you may also use the TNC 128 Automatic Mode (Full Sequence Run Mode).

Minimum-quantity lubrication system

As an alternative to conventional cooling, tools can also be cooled with an oil-air mixture over special cooling nozzles.

This technology allows dry and waste-free manufacturing.

Touch probe systems

Combined with the probing cycles of the control, triggering 3D touch probe systems facilitate setup, measuring, and monitoring during manufacturing.

Tool measurement

The following tool data is precisely determined via control cycles:

- tool length

- tool radius

- tool wear

CNC dividing unit

The CNC dividing unit is used for direct and indirect dividing with a direct dividing plate and a 24-notch dividing plate.

Center height: 100 mm

including tailstock

HEIDENHAIN TNC 128 Positioning Control

KUNZMANN’s WF 410 M is operated via the HEIDENHAIN TNC 128 positioning control. It combines the functionality of a digital readout and a positioning control for efficient manufacturing of individual part and small series.

The TNC 128 allows paraxially approaching the set nominal position.

Operational Modes:

- Manual Mode (3-axis active digital readout)

- Manual positioning

- Program run (Single Run Mode/Full Sequence Run Mode*)

- Programming

- Graphic simulation

The TNC 128 offers multiple dialogue-guided cycles with graphic simulations for a fast and convenient set-up, e.g.:

- various drilling cycles

- thread cutting

- bolt-hole circle

- hole line

- rectangular pockets/studs

- multipass milling of plane surfaces

additionally:

- tool and reference point table

- cutting data calculator

- on-screen user assistance

- data interface: USB interface, Fast Ethernet interface

Graphic simulation:

- 12.1″ color screen

- plan view

- 3-level presentation

- 3D presentation

- detail magnification

* Full Sequence Run only in combination with splash guard cabin (CE Guideline)

You can download our product brochures and layouts here:

| KUNZMANN WF 410 M product brochure |

| KUNZMANN StateViewer | |

| KUNZMANN WF 410 M layout |