WF 650 5AX

Highlights

The WF 650 5AX is a state-of-the art high-performance universal milling machine for precision single and variable batch production with a perfectly accessible working area.

The 5-axis simultaneous version of the WF 650 has a CNC tilting-rotating table and may be equipped with different spindles for numerous manufacturing options.

The special KUNZMANN features:

- elaborate cast iron column design with high stability and inherent rigidity

- high-performance motor spindle with cooling unit

- standard 38-pocket tool changer

- tilting-rotating table Ø 400 mm with large swiveling range +120°/-95°

- optimum precision due to direct path measurement in all axes

- ergonomically convenient machine with spacious front and side door and thus perfect workroom accessibility

- high-speed contouring control HEIDENHAIN TNC 640

| WORKING RANGE | |

| Longitudinal | 650 mm |

| Cross | 500 mm |

| Vertical | 450 mm |

| Main drive (100%/25% of duty cycle) | 23/44 kW |

| Spindle speed | 1-18,000 rpm |

Tool holder | SK 40 DIN ISO 7388-1 (formerly DIN 69871) / HSK 63-A DIN 69893-1 |

| Feed | up to 25 m/min |

| Control | HEIDENHAIN TNC 640 |

| Weight | approx. 5,500 kg |

| CNC tilting-rotating table | |

| Rotary table | ø 400 mm |

| T-grooves | 6 x 14 H8 |

| Table load | max. 300 kg |

| A axis tilting range | +120°/-95° |

| C axis rotary range | 360° |

| Tool changer | |

| Tool pockets | 38/60 |

| Tool change time | approx. 5 s |

| Chip-to-chip time | approx. 10 s |

| Internal cooling | 25/40 bar |

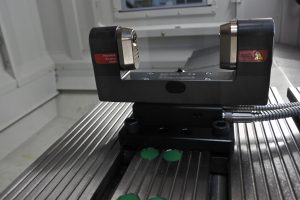

38-/60-pocket tool changer

Even the standard WF 650 5AX is equipped with a fast 38-pocket tool changer.

Without requiring more working space, the chain magazine can be extended to 60 pockets as an option.

max. tool diameter (all pockets in use): 75 mm

every other pocket in use: 150 mm

max. tool length: 300 mm

max. tool weight: 8 kg

tool change time: approx. 5 s

chip-to-chip time: 10 s

25/40-bar internal cooling

- for high-pressure coolant supply through the tool

- with maintenance-free metal-edge filter and air through the spindle

- space-saving system with a flow rate of 25 l/min at 25 or 40 bar

Slat-band chip conveyor

- for long chips, steel chips, or wool chips

- homogenous separation of various materials

- for processing with high chip volume

Conveyor height: approx. 1,250 mm

Conveyor width: approx. 350 mm

Touch probe systems

Combined with the probing cycles of the control, triggering 3D touch probe systems facilitate setup, measuring, and monitoring during manufacturing.

Tool wear control/measuring

In addition to a fast tool wear control, the control also provides cycles for the automatic gathering of tool data during the manufacturing process:

- tool length

- tool radius

- tool wear

HEIDENHAIN TNC 640 contouring control

Modern high-performance CNC control for 3D and 5-axis manufacturing of complex workpieces with short block processing time

Convenient program management due to included hard drive and USB/Fast Ethernet interfaces

Numerous graphic and simulation options

Special HEIDENHAIN TNC 640 features:

- Programming with HEIDENHAIN conversational programming language, DIN-ISO-Code

- AFR (Automatic Feed Reduction): With this innovative control feature invented by KUNZMANN, the feed rate is automatically adjusted to the spindle load.

- CAD Viewer for viewing and analyzing current 2D and 3D CAD data (STEP or IGES, e.g.)

- CAD Import (option), direct input and processing of 2D/3D contours

- KinematicsOpt, special software option for convenient measurement of rotary axes; optimization of the machine’s rotary and swiveling axes

The KinematicsOpt cycle automatically captures, traces and corrects geometric deviations. - DCM (Dynamic Collision Monitoring):

The machine stops the axes if an internal collision with known components, such as clamping devices, tools or the main spindle, may occur. The system thus avoids machine damage and considerably supports the operator.

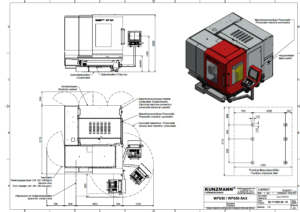

You can download our product brochures and layouts here:

| KUNZMANN WF 650 product brochure |

| KUNZMANN StateViewer | |

| KUNZMANN WF 650 layout |